American paper currency, produced by the Bureau of Engraving and Printing, is only made in two places – Washington D.C. and Fort Worth. Approximately $526 million is printed every day, over half of which originates in Fort Worth.

In 1877, the BEP became the sole producer of all U.S. currency. Fort Worth, however, did not start producing currency until the Western Currency Facility began operation in 1991.

BEP began planning for a new plant in 1985 to increase overall capacity, better serve the West and make the bureau less vulnerable to disruption. There were 83 cities interested, but thanks to Bob Dolen, the mayor of Fort Worth at the time, and other local donors, Fort Worth won the bid to begin construction.

Does money grow on trees?

No. American currency is not made from wood pulp like other paper. Instead, it is made up of 75% cotton and 25% linen. This special material is difficult to counterfeit and more durable than regular paper. In fact, a dollar bill could be folded 4,000 times before it would begin to tear, according to the Western Currency Facility.

All currency paper is made by a company called Crane Currency in Dalton, Massachusetts. This company makes material specifically for the BEP.

All currency paper is made by a company called Crane Currency in Dalton, Massachusetts. This company makes material specifically for the BEP.

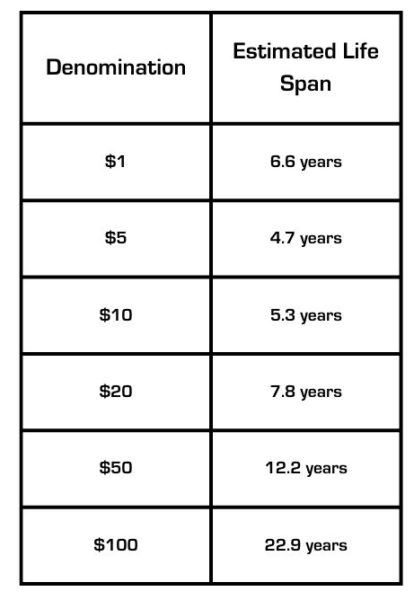

The lifespan of money depends on the denomination. Larger denominations pass between users less frequently, so they tend to last longer.

Money makers

Banknote designers draw the faces and features of a bill using traditional tools and state-of-the-art technology. Engravers then etch the designs into steel dies where they will be processed to create printing plates. Security features are regularly changed on the bill to reduce reproducibility. Some features include embedded watermarks and security threads, color shifting ink for $10 bills and higher, microprinting, color variety and the 3-D security ribbon on the current $100 bill.

Printing cash

Printing currency is one of the few times that an individual piece of paper goes through three different printing presses, according to the Western Currency Facility.

Offset printing is first. This is where the background colors are printed. Sheets of 32 or 50 notes travel through an offset printing machine where the fronts and backs are printed simultaneously. One-dollar and $2 bills do not go through this process because they do not have colored backgrounds.

The sheets then go to the back intaglio printing press. This is where the entire back of the bill is printed in green ink, including the “In God We Trust” motto that has been inscribed on every bill since 1957. Ink is applied to the engraved, recessed areas on a metal plate. The paper is placed on top of the plate and pressed together with immense pressure. The ink must dry for three days before going to the next step.

Next, the front of the bills are printed in the face intaglio printing press using the same process. The portraits, numerals, bordering, scrollwork and lettering, including the small “FW” indicating that it is made in Fort Worth, are now all complete and must dry for three more days.

Examination station

The sheets now travel to mechanical examination operations (OCIS) for a high-tech checkup. Using advanced software and camera equipment, each bill is analyzed in three-tenths of a second to ensure that there aren’t any inconsistencies or printing errors. About 97% of bills pass inspection.

Sheets are then cut in half and sent to letterpress printing operations (COPE-Pak).

Finishing touches

During COPE operations, the bills receive their final markings, including two serial numbers, the black Federal Reserve seal, the green treasury seal and Federal Reserve identification numbers.

The sheets are then sliced, sorted and wrapped. Skids of cash, or 640,000 bills, are bundled together and placed in an onsite vault until delivery. Though the bills look like real money, it is not legal tender until the Federal Reserve issues them.

The WCF is a little less than 20 miles from the TCU campus. Tours are available Tuesday through Friday, excluding federal holidays, from 8:30 a.m. to 5:30 p.m. The tour is free and will highlight each stage of money production. Visitors will be able to see millions of dollars undergoing production. No phones or cameras are allowed inside the facility.